6ES7650-0NH07-0YX1 SIMATIC PCS7 OS SERVER 547B

6ES7650-0NH07-0YX1 Detailed English Specifications (Siemens SIMATIC PCS 7 547B OS Client Rack PC) This is a 4HE 19″ rack –

6ES7650-0NH07-0YX1 Detailed English Specifications (Siemens SIMATIC PCS 7 547B OS Client Rack PC) This is a 4HE 19″ rack –

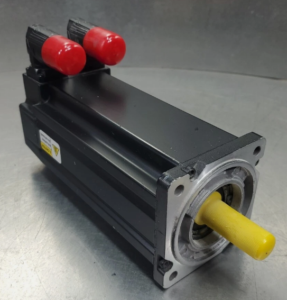

Bulletin MPL – Low-Inertia Brushless Servo Motors Product, 460 V, Frame Size 3 = 100 mm (3.94 in.), Stack Length

1783-BMS06SA Allen-Bradley Switch, Managed Ethernet, 6 Port, 4 x RJ45, 2 x SFP Slot Technical specifications for 1783-BMS06SA Manufacturer Allen

1606-XLS960E-3 ALLEN-BRADLEY 1606 Power Supplies 1606-XLS960E-3: Performance Power Supply, 24-28V DC, 960 W, 3-Phase 480V AC wide range / 600V

6SL3352-1AE37-5BA1 Detailed English Specifications (Siemens SINAMICS S120 Power Block) This is a replacement power block for the V/W phases of

20-HIM-B1 Allen-Bradley 20-HIM-B1 Powerflex Architecture Class Technical specifications for 20-HIM-B1 Manufacturer Allen Bradley Product Type HIM Bezel Product Line PowerFlex

1783-CMS10DN Stratix 5200 10 Port Switch Manufacturer: Rockwell Automation Mounting Type: Din Rail Name: Rockwell Automation 1783-CMS10DN Stratix® 5200 Switch,

5094-RTB32V 5094 RTB 32 Input Screw 5094,FLEX 5000 Modules Technical specifications for 5094-RTB32V Manufacturer Allen Bradley Category PLCs Product Line

EurAutomation.com is a professional supplier of industrial automation products, providing integrated solutions, such as PLC, HMI, CNC, DRIVES, CNC, INVERTER, VFDs, frequency converter cabinet, DC speed control cabinet, widely used in industrial automation, process automation, humanoid robots, intelligent factories, unmanned workshops, no matter what your procurement needs are, you only need to send an email. We will serve you as soon as possible.